When choosing a durable, resilient, and versatile building board for your construction project, MGO board (Magnesium Oxide board) and cement board are two leading contenders. Both offer significant advantages over traditional materials like drywall, especially in challenging environments. However, they possess distinct characteristics that make them more suitable for different applications. Understanding these differences is key to making the best choice for your building’s longevity and performance.

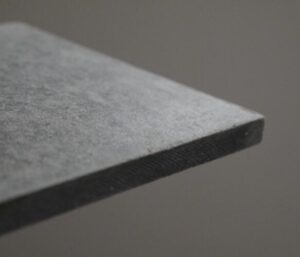

MGO Board: Primarily composed of magnesium oxide, magnesium without chloride, perlite, wood fiber, and reinforced with a high-strength fiberglass mesh. This mineral-based composition is what gives it many of its unique properties.

Cement Board: Typically made from Portland cement, silica, and reinforcing fibers (cellulose or fiberglass). It’s essentially a concrete-like panel designed for specific building applications.

MGO Board vs. Cement Board: A Detailed Comparison

Let’s break down how these two popular building materials stack up across critical performance metrics:

1. Fire Resistance: Superior Safety Performance

MGO Board: Excels in fire safety. It is inherently fire-rated and non-combustible, meaning it won’t ignite or contribute fuel to a fire. MGO boards often achieve high fire ratings (e.g., 1-4 hours) and release minimal to no smoke or toxic fumes when exposed to flame, making them a top choice for enhanced safety in any structure, especially in high-density areas like Singapore.

Cement Board: While also non-combustible and offering good fire resistance, its performance can vary. It resists flame spread and does not burn, but some types may crack under extreme thermal shock. Generally, it’s considered fire-resistant but may not achieve the same extended fire ratings as specialized MGO boards without additional assemblies.

2. Water & Moisture Resistance: Essential for Humid Climates

MGO Board: Highly resistant to water, moisture, and humidity. It does not swell, rot, delaminate, or deteriorate even with prolonged exposure to moisture, making it an excellent choice for wet areas like bathrooms, kitchens, and exterior cladding. Its alkaline nature naturally inhibits mold, mildew, and fungi growth.

Cement Board: Designed to be water-resistant and is commonly used as a tile backer board in wet areas. While it won’t rot, it can absorb water and may require additional waterproofing membranes in shower areas to prevent water from reaching the substrate behind it. It is less susceptible to mold than gypsum but can still support some growth under persistent moisture.

3. Weight & Installation: A Key Consideration

MGO Board: Generally lighter than cement board of comparable thickness, which can simplify handling and speed up installation. It’s often easier to cut (scoring and snapping for thinner boards, or using a carbide-tipped saw blade for thicker ones) and less abrasive on tools.

Cement Board: Can be quite heavy, especially thicker panels, requiring more effort for lifting and maneuvering. It is also very hard and abrasive, necessitating specialized cutting tools (like a diamond-tipped blade) and often producing more dust.

4. Strength & Durability: Long-Lasting Performance

MGO Board: Offers excellent strength-to-weight ratio and good impact resistance due to its fiberglass mesh reinforcement. It provides a stable and rigid surface for various finishes.

Cement Board: Extremely strong and durable, providing a very rigid and stable substrate. Its density gives it high impact resistance, making it suitable for high-traffic areas.

5. Flexibility: Design Possibilities

MGO Board: Some MGO boards offer a degree of flexibility, allowing for curved wall applications or unique architectural designs that are difficult to achieve with rigid cement board.

Cement Board: Very rigid and generally not suitable for curving without specialized techniques or smaller pieces.

6. Environmental Impact & Health: Sustainable Choices

MGO Board: Considered a sustainable and eco-friendly material. Its production is typically less energy-intensive, and it contains no asbestos, formaldehyde, or other harmful chemicals. Its natural mold resistance contributes to healthier indoor air quality.

Cement Board: Made from abundant raw materials. While durable, its production is more energy-intensive than MGO board’s, and it can create significant silica dust when cut, requiring proper ventilation and PPE during installation.

Both MGO board and cement board are superior alternatives to traditional drywall in areas requiring enhanced durability and moisture resistance.

JUL

2025