The question of whether MgSO4 board is a structural sheathing material is complex and depends on the specific product and its code approval, but the general answer is Yes, specific, high-density MgSO4 formulations are engineered and approved for use as structural sheathing

The question of whether MgSO4 board is a structural sheathing material is complex and depends on the specific product and its code approval, but the general answer is Yes, specific, high-density MgSO4 formulations are engineered and approved for use as structural sheathing

Here is a breakdown:

- Structural vs. Non-Structural

- Sheathing is a board or panel material covering the outer wall framing (studs).

- Structural Sheathing (like OSB or plywood) provides lateral load resistance (shear strength) to the building, helping it withstand forces like wind and earthquakes, and is required to have specific code-compliant strength values.

- Non-Structural Sheathing (like gypsum sheathing) primarily serves as a substrate for cladding, a weather barrier, or a fire-rated layer, but does not contribute to the building’s racking strength.

- MgSO4 Board Structural Performance

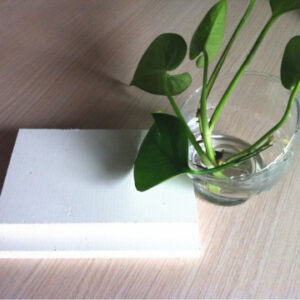

High-quality Magnesium Sulfate (MgSO4) boards are often specifically manufactured to meet the structural requirements for wall sheathing and subfloors. They generally offer:

- High Compressive and Flexural Strength: The dense, mineral composition reinforced with fiberglass mesh provides significant resistance to impact and bending forces.

- Shear Strength (Racking Resistance): Structural-grade MgSO4 products are tested to demonstrate shear values that allow them to be used as a direct replacement for OSB or plywood shear panels. They contribute to the structure’s ability to resist forces that try to push the wall out of square.

- Dimensional Stability: The MgSO4 formulation is crucial here, as it provides the stability needed for exterior structural use. Unlike older MgCl2 boards, the sulfate-based boards do not degrade or lose strength due to moisture absorption or corrosion, ensuring long-term structural integrity.

- Code and Approval is Key

Not all MGO boards are structural. To be used as code-compliant structural sheathing, the MgSO4 product must have a valid evaluation report (such as an ICC-ES report in the US) that specifically rates it for:

- Structural Sheathing: Defining the allowed stud spacing and fastener schedules to achieve the required shear wall ratings.

- Fire-Rated Assemblies: Often a major advantage, as MGO is non-combustible (Class A/A1 fire rating).

In short, when you see an MgSO4 board marketed as Structural Wall Sheathing or Structural Panel, it means the manufacturer has tested and certified it to meet the necessary building code performance criteria to provide shear strength. Always verify the specific product’s official code report.

OCT

2025