In the world of modern construction, finding materials that are both sustainable and high-performing is a key challenge. One innovative solution that is gaining significant traction is the Magnesium Oxide (MGO) Structural Insulated Panel (SIP). These panels are a revolutionary building material that offers a compelling alternative to traditional stick-frame construction.

In the world of modern construction, finding materials that are both sustainable and high-performing is a key challenge. One innovative solution that is gaining significant traction is the Magnesium Oxide (MGO) Structural Insulated Panel (SIP). These panels are a revolutionary building material that offers a compelling alternative to traditional stick-frame construction.

What are MGO SIPs?

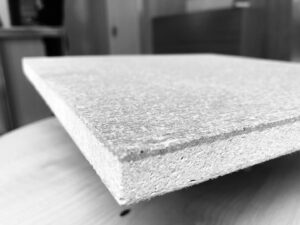

At its core, an MGO SIP is a composite building material consisting of two layers of MGO board with a rigid foam insulation core sandwiched between them. The MGO board acts as both the structural sheathing and the interior/exterior finish, while the foam core provides exceptional thermal insulation.

The magnesium oxide board itself is a naturally fire-resistant and water-resistant mineral. It’s made from a combination of magnesium oxide, magnesium chloride, and other materials. The foam insulation is typically made from expanded polystyrene (EPS) or extruded polystyrene (XPS), both of which are excellent insulators.

Key Advantages of MGO SIPs

The unique combination of materials in MGO SIPs provides a host of benefits that make them ideal for a wide range of building projects:

- Exceptional Durability and Strength: MGO SIPs are incredibly strong and resilient. They have a high load-bearing capacity and are resistant to impact, offering a robust structural solution for walls, floors, and roofs.

- Superior Fire Resistance: One of the most significant advantages of MGO board is its natural fire-resistant properties. Unlike wood, it doesn’t burn, making MGO SIPs an excellent choice for buildings where fire safety is a priority.

- High Thermal Performance: The continuous foam insulation core eliminates the thermal bridging that is common in traditional stick-frame construction. This results in an extremely tight and well-insulated building envelope, significantly reducing energy consumption for heating and cooling.

- Mold and Mildew Resistance: MGO is an inorganic material that doesn’t provide a food source for mold or mildew. Its water-resistant properties also help prevent moisture from accumulating within the walls, creating a healthier indoor environment.

- Speed of Construction: MGO SIPs are prefabricated in a factory and delivered to the construction site ready for installation. This dramatically reduces on-site construction time and labor costs. A structure can be erected in a fraction of the time it would take with conventional methods.

- Environmentally Friendly: MGO is made from naturally occurring materials and has a low carbon footprint. The panels’ high energy efficiency also contributes to a more sustainable building by reducing the long-term energy demands of the structure.

Applications of MGO SIPs

The versatility of MGO SIPs makes them suitable for a wide variety of construction applications, from residential homes to commercial and industrial buildings. They are increasingly being used for:

- Single-Family Homes: Providing an energy-efficient and durable building envelope.

- Modular and Prefabricated Buildings: Their pre-engineered nature is perfect for this type of construction.

- Schools and Community Centers: Where fire safety and durability are essential.

- Agricultural Buildings: Such as barns and storage facilities, due to their resistance to moisture and pests.

The Future of Construction

As we move toward a future where sustainability and energy efficiency are paramount, MGO SIPs offer a powerful solution. They provide a building method that is not only faster and stronger but also more environmentally conscious. By combining the benefits of exceptional insulation with a durable and fire-resistant structural core, MGO SIPs are helping to shape a new era of smarter, safer, and more efficient construction.

SEP

2025